Franziska Ritter and Pablo Dornhege, both digital.DTHG project leads, sat down with Andreas Gause, Director of Marketing & Business Development at Gerriets, to talk about digital transformation in the field of theatre.For 70 years, the family-run company has been a world market leader in stage and event requisites. Their product portfolio includes curtains, films and backdrops, decorative fabrics, stage velours and fancy materials that are all manufactured onsite as well as stage technology such as hoist and rail systems. The virtual assembly instruction prototype, developed using the TRUMPF 95 curtain rail as an example by the digital.DTHG team in cooperation with Gerriets, is meant to make it easier to work on and behind the stage. This conversation took place on February 7, 2022 at the Assmann showroom in Berlin.

Over the past two years, there has been a lot of development in the field of theatre regarding digitalization and digital competence. Where do you think your company is at when it comes to digital competence?

At Gerriets, we’re looking at two areas: First, we have the artistic field that we support with our products to facilitate the staging of digitally motivated productions. An example for this would be our classic projection films for front, back or combined projections as well as soft edge, panoramic or dome projections. We also have visual effect materials and real 3D projections like our Pepper’s Ghost film or our 3D projection gauze, both of which make it possible to create amazing hologram projections. The second area in which digitization is progressing is our internal processes. This includes our inventory control system, calculation tools, stockkeeping and the CRM systems for customer service as well as our web shop, which works very well with integrated CMS tools. All our products have been fully digitized as 2D and 3D CAD drawings so architects and planners can already use them.

First ideas at the Kick Off Meeting at Akademie für Theater und Digitalität Dortmund 2020

Together, we have created a prototype for digital assembly instructions for the TRUMPF 95 curtain rail and we have run several tests including one with the technical team at the German Theatre in Berlin. What are some of the conclusions that you can draw from this?

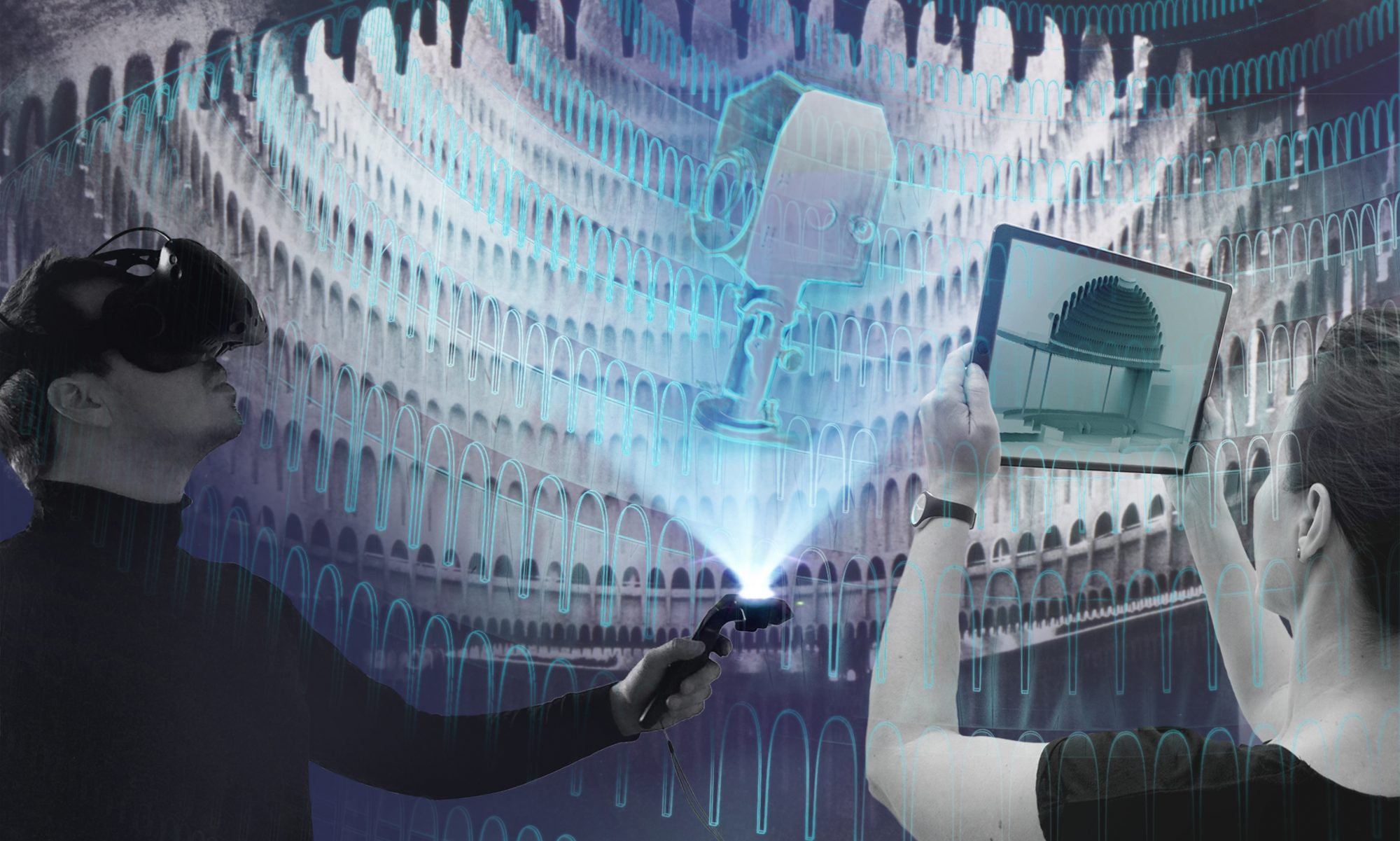

We are always open to trying new things and we like investing both time and energy into new technologies. When you first told me about what you were planning to do in our first meeting at Dortmund’s Academy for Theatre and Digitality, I initially had trouble imagining what augmented assembly instructions might look like. In the workshops that followed, I began to see not only the technical feasibility but also the potential value: One of the big advantages is the plastic and therefore very realistic presentation. Someone who has never worked with a rail system like this before can just put on the glasses and the pieces are virtually projected onto the stage. Then, all that needs to be done is to fill in the „blank spaces“. The system shows where the pieces need to be placed. This saves time and helps with understanding both the setup and the interaction of the different elements – this is a great advantage, especially compared to a classic paper manual that requires you to find the right page at the right time.

Our collaboration and experiments with the prototype have shown me and our company that this can be a valuable tool if we continue to develop it. There still is a bit of work to do to take it from an experiment to an actual tool but I can already see the value it will bring.

What would be the next step to further develop the prototype?

The parts that are most exciting to us are design and configuration. Somewhere in the world a customer can connect to our website, get on stage, create their own individual system, visualize it in real time and, for example, discuss it with their director. It doesn‘t have to be perfect and final because later, there will be an individual consultation.

Our goal is to make it possible to use a menu guidance to freely configure a modular rail system and have the system automatically configure the correct assembly instructions from the modules. There is a great advantage here because since we ship our products globally, augmented, three-dimensional instructions are much more accessible and comprehensible. When we provide a printed manual, we don’t have this plasticity and there is more potential for misunderstandings. There is no longer the need for an “old hand“ who has set up the system 60 times. But this can be useful when training new our current employees. The next step would be smart FAQs so that questions can be answered on site. Ideally via speech recognition – this way, a person can use the system and it will feel like somebody is standing next to them and explaining the product.

At the Deutsches Theater Berlin, Andreas Gause shows the digital.DTHG team the TRUMPF 95 curtain track in all its components – completely analogue!

Based on your experience with the prototype: What other scenarios can you imagine at your own business?

I can think of several scenarios, for example project acquisition. interested customers can get a first idea of our products or test a virtual curtain rail in their own theatre before our first consultation. This way, the customer can specify their own requirements better and discuss them with all the stakeholders at the theatre. If there are any questions, an expert can digitally join the conversation and discuss the customer’s needs. During an on-site consultation, the simulation could be supported with AR glasses – bringing augmented reality onto the stage. One thing that is important to us is the fact that a personal conversation can’t be replaced by digital tools. But it can be prepared for with technology so that we can make the most of the available time and focus on what‘s most important during our conversation.

In this case, the live-configuration and adjustment tool can be utilized by the consultant. The system checks the components for compatibility and the final set up can be visualized right there in the room. This visualization goes way beyond a regular on-screen 3D rendering. Since we can see the visualization on our human scale, it becomes much more engaging, regardless of whether we see it through glasses or through our smartphones. It is much easier to assess. Once everything has been cleared on site, the configuration can then be passed on to the planning department.

Our team could also use a tool like this while preparing for a complicated on-site assembly. Technical employees at theatres all over the world can familiarise themselves with the specifications of our products and practise controlling them – even before the systems have been delivered and set up. This way, installations can be prepared for in a useful manner, which is especially helpful in remote locations.

The technic team of the Deutsche Theater Berlin tests the tablet version of the WebXR prototype, in the background the TRUMPF 95 curtain track successfully set up with it.

You recently tested the prototype in a class with trainees. What were your experiences?

We think we can use a tool like this in the training of our industrial mechanics as well as in the preparation and training of employees who will be sent off to assemble systems. We already follow a “learning by doing“ approach but we do this using the actual object. That means we do this on real construction sites, which is a lot of work. Using this tool for training purposes means that augmented reality – in this case, virtual reality – helps people get to know a product. They assemble a “virtual” setup, either alone or with a group of people.

And, unlike working with assembly instructions, we don’t even need the actual object. We can practise the planning steps and think about how to best set up a system in a particular room. In this case, technology is much more than a gimmick that delights our trainees and students. It is the hands-on effect, the learning with the object, that has the greatest effect. And this works even if the object is virtual and simulated. And it doesn‘t only work in our own rooms, but also in its (virtual) place of use. This tool can also be very useful in training sessions with our global distributors. This way, our partners and subsidiaries can familiarise themselves with new products without having to travel to our headquarters. This also has a positive effect on our climate.

What is your wish for theatres in the future?

Theatre is a field that works in a very traditional way in many areas – both on stage and in the workshops. Catalogues, product descriptions, price sheets, and manuals are frequently used in a printed format. It does not necessarily promote digital ways of working. It seems to me that the creative industries are more open to change, for example the event industry seems to be quicker. But this is beginning to change. We see more and more acceptance for digital tools, and things like price sheets and catalogues are more frequently accepted as digital documents. And as the generational change at theatres and workshops continues, other digital applications will become more common.

Franziska Ritter guides Andreas Gause through the virtual assembly instructions in VR – completely digitally!

What needs to be done to make sure a digital cultural change can take place across the board?

Theatres still work in a very analogue manner. One reason for this is that not everyone is aware of all the possibilities that digital tools offer. I can imagine that this is the direction we will be going in, though. Especially in the field of stage design. People will say: “What will it look like if I add a Gobelin net here? How will the scenery change if I use a different fabric instead? And how will our projection look?” This will touch on your other project area, the virtual construction rehearsal. Right now, we are still a long way from that but in other areas, technological tools are not only requested but also very commonly used for visualisation and planning. At some point, similar demands will become common in the theatre as well. But this will require a collaboration between manufacturers. Maybe this cooperation could be moderated by the associations. Politics, associations, universities and manufacturers must work together – the private sector will most likely not be able to foster a sustainable development on its own. I think associations, universities and manufacturers generally need to connect and work together

more closely.

Fotos: Maria Bürger